Please do not place an order directly. Please provide the 3D drawing file or sample you need to customize and then give you a quotation RFQ send to email: [email protected]

Effective Production Problem Solutions:

At EasoonMade, we understand the complexities of the production process and the challenges that can arise. Our team of experienced professionals collaborates closely with your business to identify and address production issues effectively. With our comprehensive knowledge and problem-solving skills, we develop tailored solutions that improve product quality, reduce downtime, and increase overall productivity.

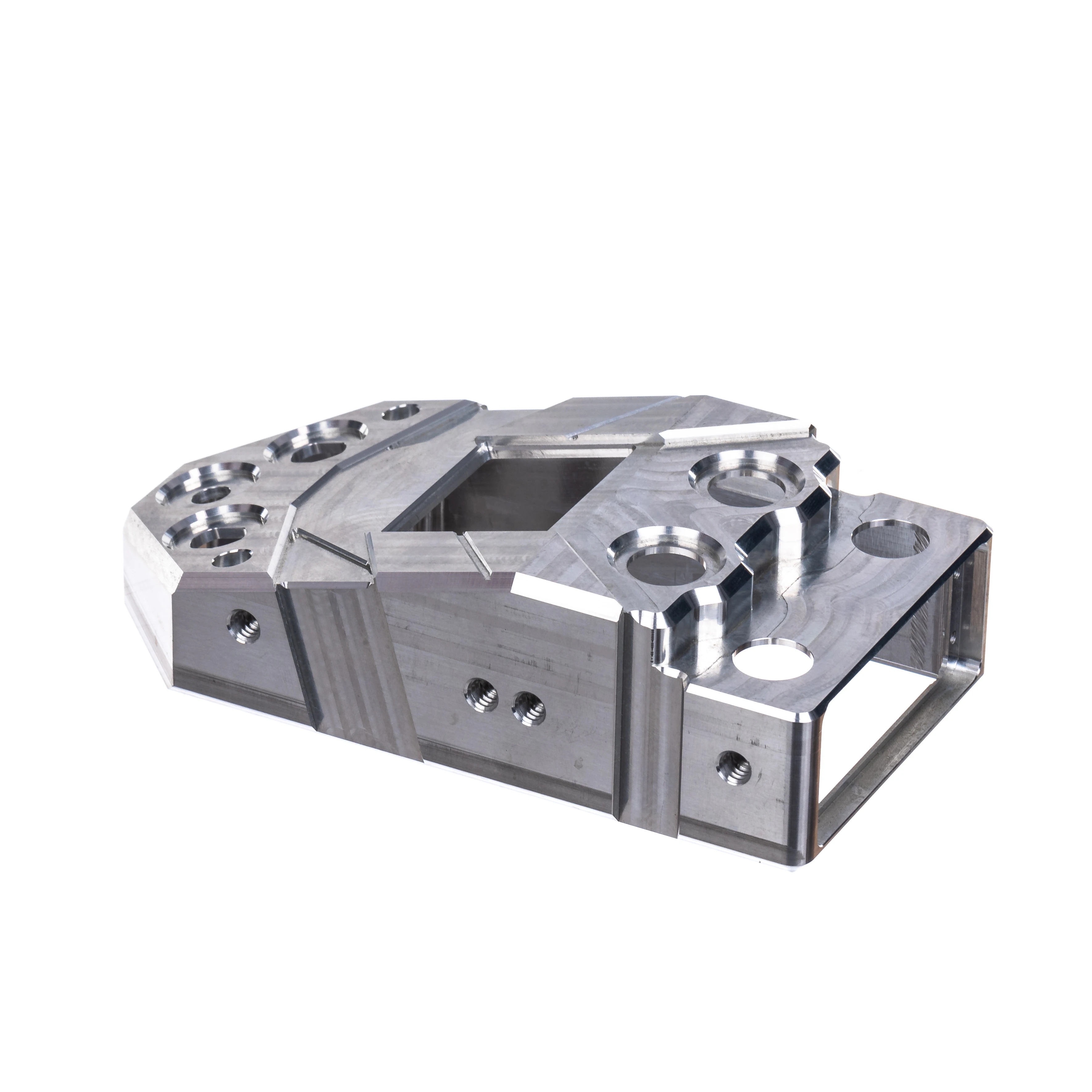

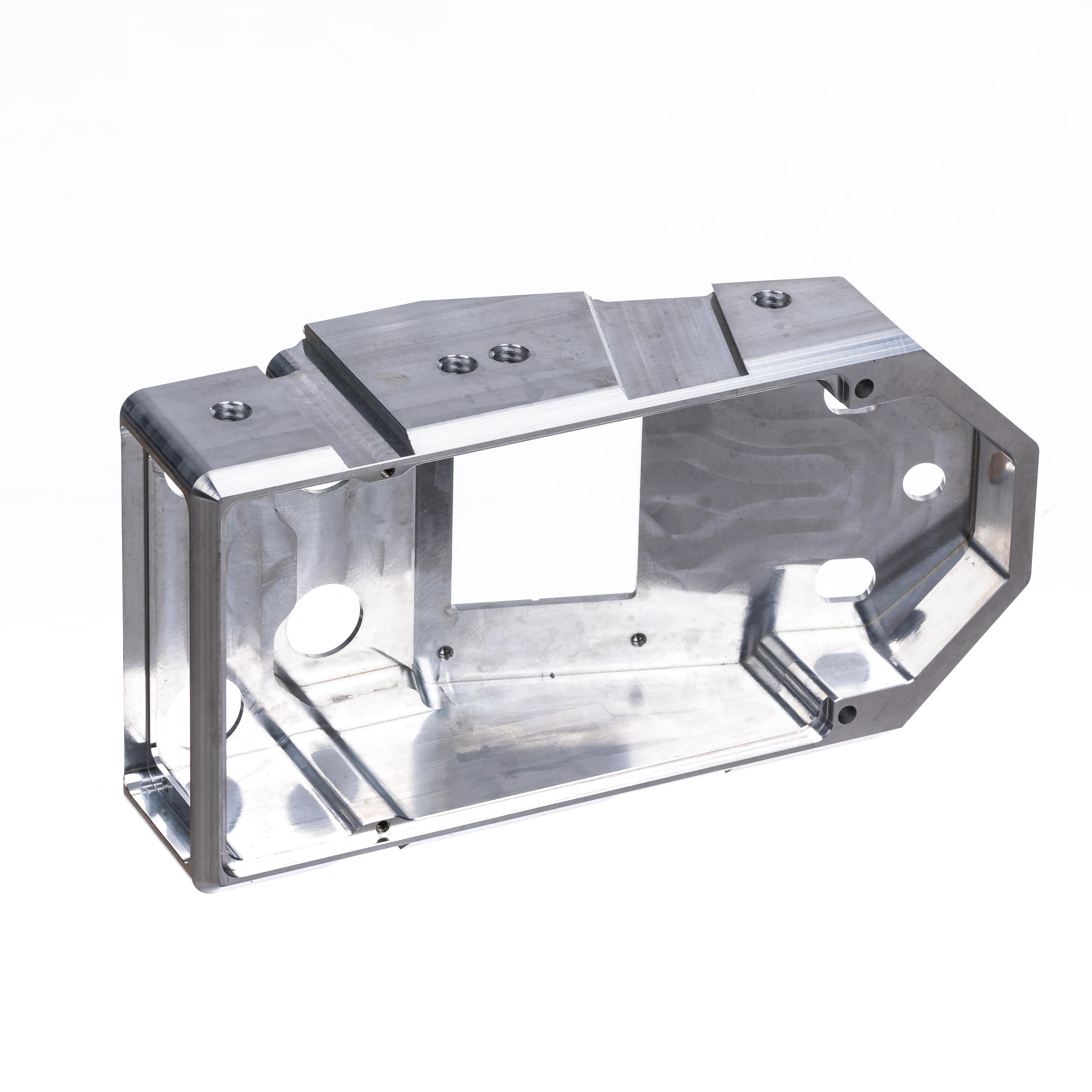

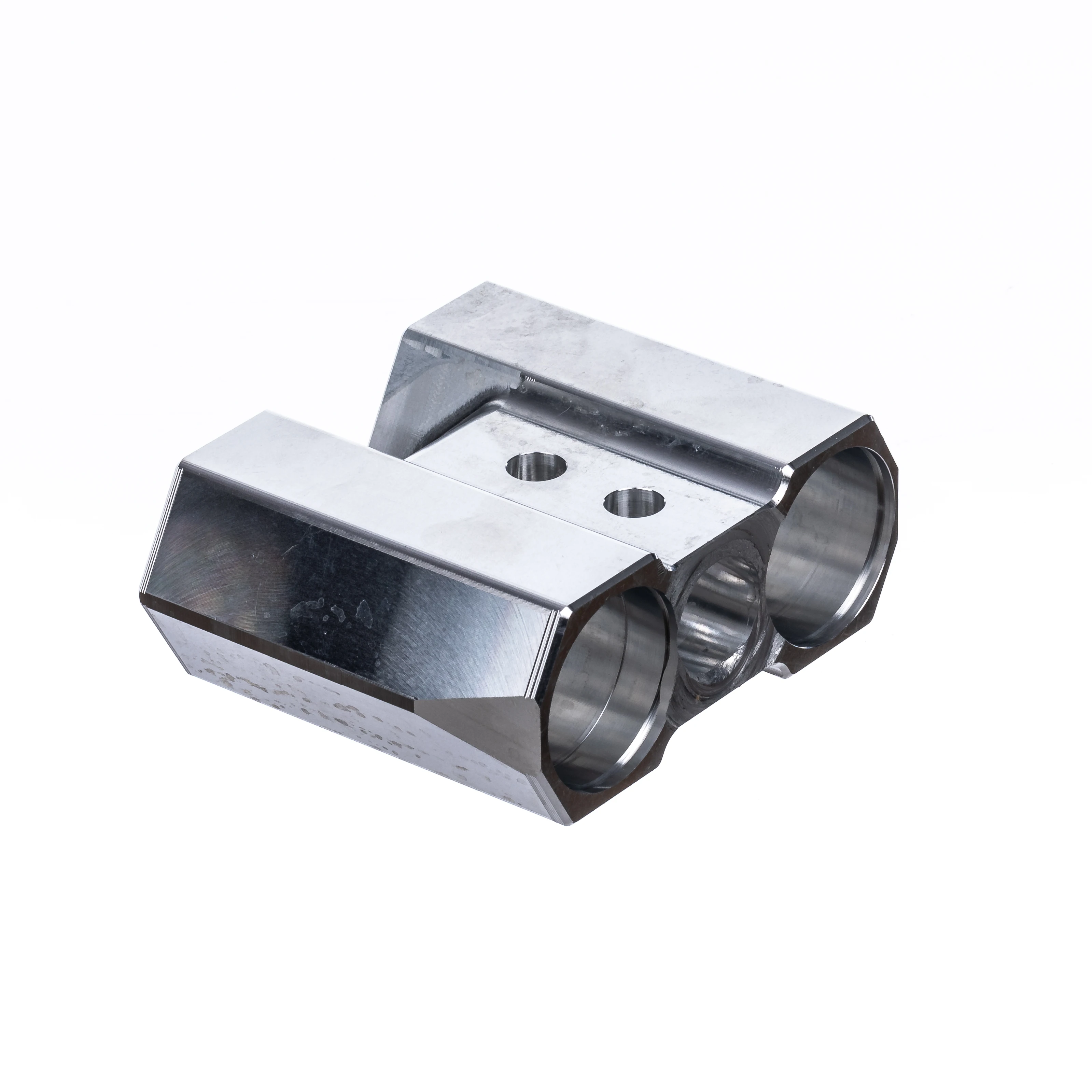

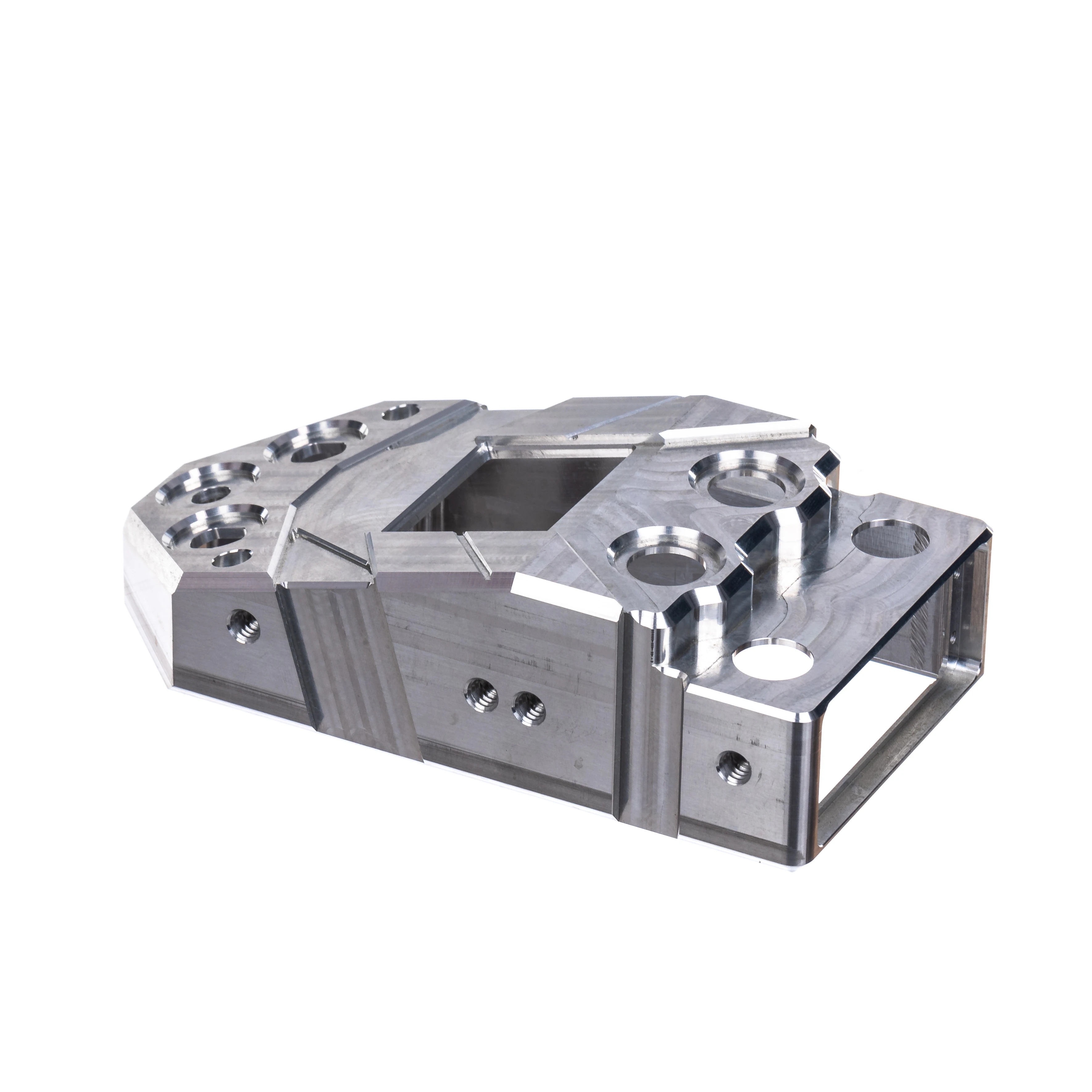

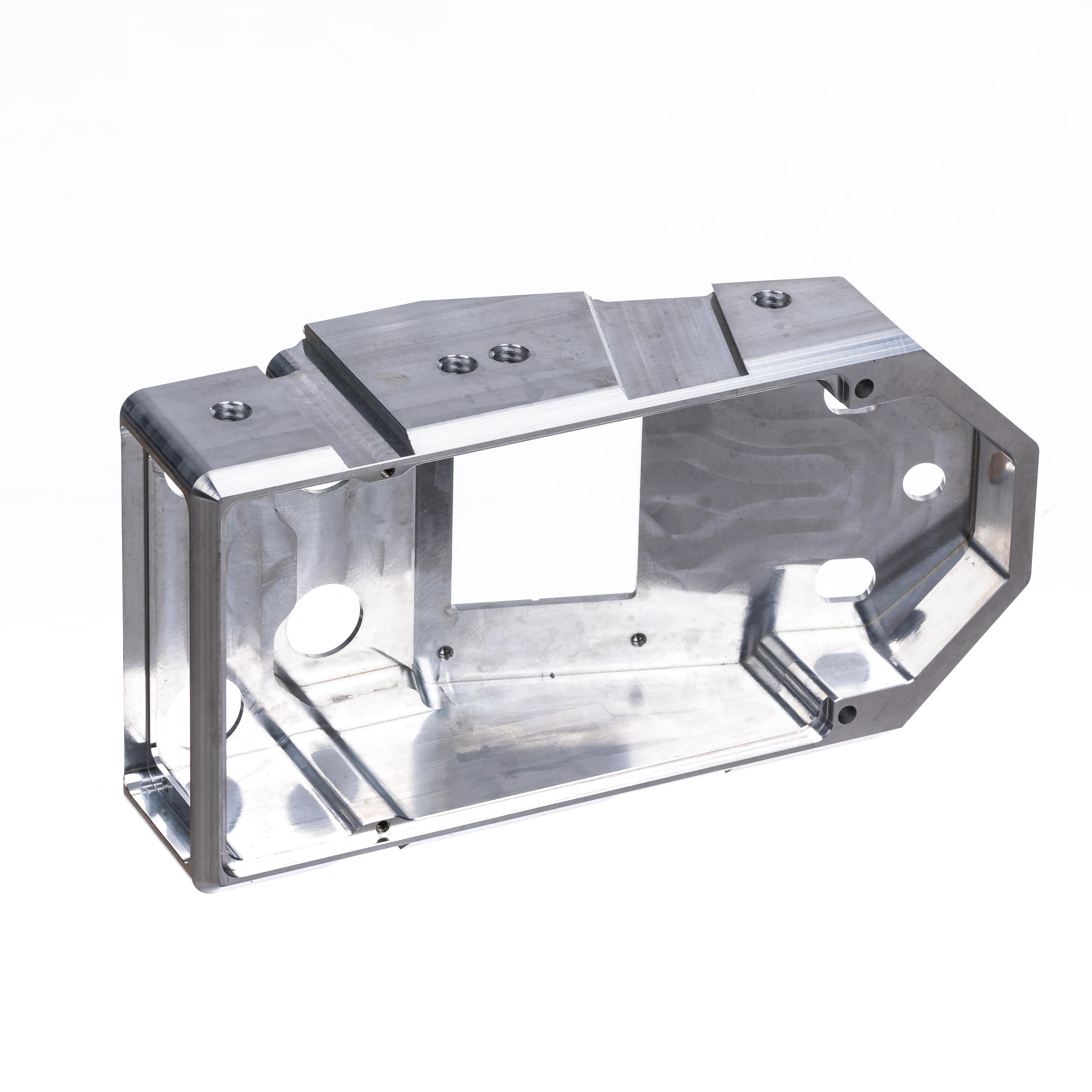

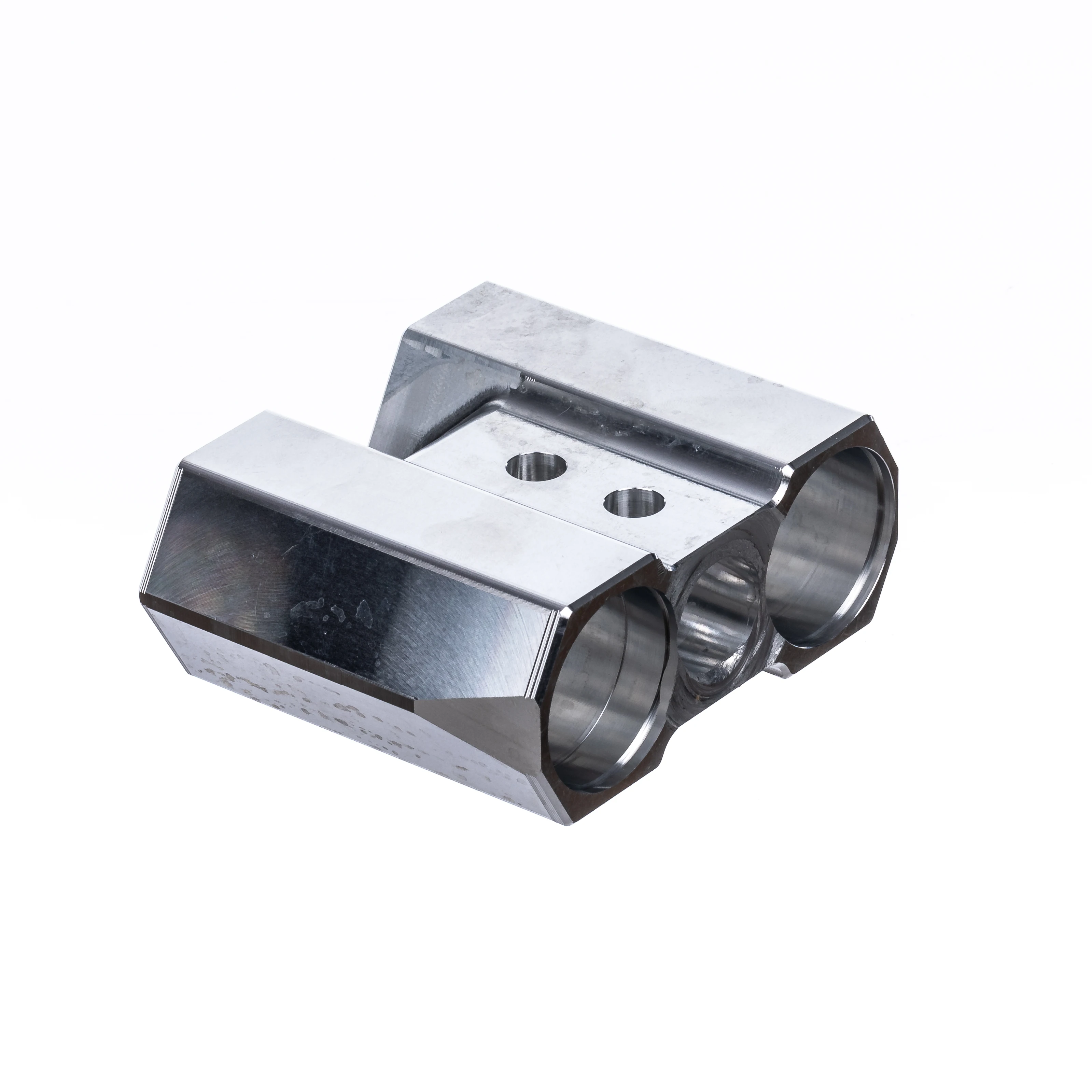

Custom Fixtures for Enhanced Efficiency:

We specialize in designing and manufacturing custom fixtures that optimize workflow and streamline production. Our fixtures are carefully crafted to meet your specific requirements and ensure precise alignment and positioning. By using our custom fixtures, you can reduce production errors, enhance accuracy, and minimize waste, ultimately saving time and costs.

Product Description

| Name |

manufacturing rapid prototype machined parts, rapid prototyping cnc machining service|rapid sheet metal prototyping |

| Materials |

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc.Other Special Materials:Lucite/Nylon/wood/titanium/etc |

| Surface Treatment |

Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

| Tolerance |

+/-0.05mm, 100% QC quality inspection before delivery, can provide quality inspection form |

| Testing equipment |

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement |

| Processing |

CNC turning, CNC milling, CNC machining, Laser cutting, Grinding, EDM wire cutting |

| File Formats |

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| Service Project |

To provide production design, production and technical service, mould development and processing, etc |

| Quality Assurance |

ISO9001/14000:2015 Certified.SGS

|

rapid sheet metal prototyping

Industrial design and engineering consultants are some of the most innovative and creative

companies on earth. You are also the backbone of our business, and YX works with product designers around the world to prototype and manufacture innovative and cutting-edge products

and designs. Develop and improve product ideas while saving a lot of time and money.

Our extensive customer-centric services allow you to iterate quickly and quickly deliver customized solutions to your customers. rapid sheet metal prototyping

We understand the needs of the product development timeline and the need to achieve perfection for the first time. At Easoon, we work with you to ensure that your needs are met and exceeded.

Conceptual design is so important in the design process

Because the results of conceptual design will enter into the following detailed design and engineering process. The longer your concept waits to be determined, the more expensive development will become. In fact, the success of a product depends on being conceived correctly in the first place. Don't underestimate the importance of proof of concept prototypes and move on without proving to yourself and others that your idea is technically feasible..

Steps to turn conceptual design into reality

With the continuous progress of society, various industries are constantly developing, and the progress of various industries is due to the relevant driving factors. Industrial product design is very critical to the whole era, and we want to do these designs well, we must make the design meet two conditions, so that it can play a role and help the development of society.

Once the product requirements have been identified, your project will enter the conceptual design phase before starting detailed design. Requirements (Ideas) – > conceptual design – > CAD modeling – > DFM analysis – > conceptual prototype – > Design Optimization

Using 3D software and 3D modeling (Pro / E, Solidworks, freeform, zbuse...) to build 3D file. Assemble parts to create CAD models to check for potential problems before manufacturing any physical parts. The assembly of the initial concept prototype is a key step in the process of verifying previous design assumptions. Physical tests confirm that the prototype meets the performance requirements established in the concept phase.

When design is used for manufacturability (DFM) analysis, parts and components are designed to ensure that they are suitable for manufacturing capability. Your detailed design will be built using 3D printing or other rapid prototyping technologies. At this stage, your design will begin to look and be realistic

Easoar product design has many years of experience, in the design process, they not only pay attention to the practicality of the product, but also pay attention to the specific aesthetic value. In this era, people are no longer pursuing simple practical functions, but also hope that it can be better seen in the appearance and other aspects, so that it will be more comfortable to use. In the whole design process, we need to have good innovative thinking, but what value will be better promoted. Easoar product design process, not only to have practical functions, but also to have a good aesthetic value. In the whole design, with these two factors at the same time, the final design will be successful, and after production, it will be more in line with the needs of the times, and will be more secure for future sales and use. Don't think that design is a very casual thing, and we have a basis in the process of doing it.

Industrial product design - structure design

Industrial product design is composed of two parts: appearance design and structure design. The appearance design is more profound, which requires the designer to have the art foundation, aesthetic view and creative inspiration to design a good product. In many OEM factories, the appearance is usually provided by customers.

Structure design is to further complete the product function and internal structure design based on the appearance design. The electronic product structure design is generally composed of PCB and electronic components. It is mainly to fix and operate PCBs and electronic components in the most convenient way. Designers need to have

Certain structural design experience, to ensure that the mold can be made, injection molding products, mold out of the mold, assembly gap fit, good assembly of accessories. This requires continuous learning of structural design, summing up experience, going to the production line to see the staff, production operation, processing and assembly, and understanding of mold processing, materials and technology, and mold structure. For some more complex functional products, we need to use more physical knowledge, mechanical principles, such as lever principle, gear movement, gear ratio, motor speed adjustment...

What should be considered in product structure design

Making numbers seems arbitrary, but at the same time, it is restricted by many factors. When you can consider all the problems clearly, the final design will be more successful and can be used only after it is put into production. What factors need to be considered in the process of product structure design? Now let's go further.

Real design companies with many years of experience will certainly consider the practical factors in the process of structural design. Just like easoar product design, every time they design, they always consider the actual situation. Some of them are whether they are feasible in the process of production and processing, and whether they can bring more convenience and guarantee in the process of using. These aspects are all realistic factors. To understand these situations clearly will be more secure for future use.

At this time, we need continuous development in the aspect of design. Innovation can promote the progress of the industry and social development. When we have a better sense of innovation both inside and outside in the process of design, then we can guarantee the things produced later. In the process of doing, we must really consider these situations.

In the process of product structure design, we should consider the practical feasibility factors, but we should also achieve innovation. To be able to do these two things well, not only can we use the products, but also can continuously promote the progress of the whole industry in the process of innovation. Innovation is not easy, but we need to keep trying and do it seriously, so we can do better and better in the future.

3D solid modeling will be completed efficiently

3D solid modeling will be completed efficiently

Freeform 3D, a computer-aided system that uses the most tactile to complete 3D modeling, has better drawing effect, so it can be better in 3D design and construction. After all, more scientific software is very helpful in completing 3D drawing for designers, and the presentation of effect is also very prominent, so we still have to make a better choice.

Through freeform 3D drawing, we can have a better three-dimensional picture presentation, and can show the designer's inspiration, and complete the design of the model through the sense of touch. The design of the architecture is very useful. Moreover, through it, the designer can carve out his own 3D drawing form at will.

The use of advanced computer-aided design system, can provide better service for people, but also in quality assurance better. Of course, we can see that freeform 3D drawing has been recognized. It is better in effect and can be better reflected. If it can be better in related services, it will definitely have a better embodiment in terms of advantages.

Relatively speaking, to ensure the effect of 3D modeling, we need to better deal with 3D model design and structure construction, so as to achieve better overall effect and better performance in reliability. This is certainly of great help to obtain better service. After all, the benefits of better auxiliary design system are obvious, which can bring more benefits for product model design.

Using 3D solid modeling will be able to complete 3D modeling efficiently

3D product modeling can provide solutions for industrial product design

All kinds of industrial product design need more perfect solutions. At this time, 3D modeling is a very good way. It can better design various industrial products. The overall design from appearance to structure will be an important premise for products to be accepted by the market. Using the latest modeling design software and 3D printing technology, we can quickly produce higher quality products.

The determination of high-quality industrial product design scheme needs to be better grasped by the designer, so that it can be better in benefit and fully meet the requirements in advantages. If the reliability is better, the customers will be more assured, which will certainly help to obtain better quality assurance.

Through 3D modeling, it can provide guidance for the processing of industrial products, but also has greater advantages in product design perfection and quality assurance. Therefore, we should make better choices, and then better in quality, so it is necessary to make better choices, and then get better performance.

More excellent 3D model design and construction processing, which will certainly have a positive effect on the processing and manufacturing of industrial products, and will definitely be better in the overall effect. If we can grasp the service better, we can certainly make the design of various products better, and then the effect of product design will be more prominent.

3D product modeling can provide solutions for industrial product design

What is the main meaning of industrial 3D modeling

The model has its own value and function in many occasions. When we pay attention to it, we need to consider many comprehensive factors. I believe that many people want to know whether the modeling is very complicated when they pay attention to 3D modeling? In fact, this is not very difficult. Now it is relatively simple. The key is how to select the right model, so that we can better design.

Since the modeling itself is not very complicated, I believe that many people will choose to see some pictures at the beginning. After understanding the basic information of the pictures, they can know the specific situation, ensure that they can be used safely, and there are still many benefits that industrial product design can bring. As long as we choose with confidence, we can know what is It's easier to do.

In fact, when we really pay attention to it, we can find that software is basically used for modeling, and the actual modeling method is not the same. In this way, we can still see a lot of practical value or know some other advantages when we pay attention to and choose from, after all, different models play their own roles The effects are different.

In this way, when you really pay attention to 3D modeling, you can know that the modeling method is very simple, we need to use it reasonably according to some specific performance, and we can also see which word-of-mouth is better, so some benefits that can be brought will be more obvious. After all, some values of the model itself are very high, which is indeed necessary Pay more attention to it.

Will 3D modeling be complicated?

The model has its own value and function in many occasions. When we pay attention to it, we need to consider many comprehensive factors. I believe that many people want to know whether the modeling is very complicated when they pay attention to 3D modeling? In fact, this is not very difficult. Now it is relatively simple. The key is how to select the right model, so that we can better design.

Since the modeling itself is not very complicated, I believe that many people will choose to see some pictures at the beginning. After understanding the basic information of the pictures, they can know the specific situation, ensure that they can be used safely, and there are still many benefits that industrial product design can bring. As long as we choose with confidence, we can know what is It's easier to do.

In fact, when we really pay attention to it, we can find that software is basically used for modeling, and the actual modeling method is not the same. In this way, we can still see a lot of practical value or know some other advantages when we pay attention to and choose from, after all, different models play their own roles The effects are different.

In this way, when you really pay attention to 3D modeling, you can know that the modeling method is very simple, we need to use it reasonably according to some specific performance, and we can also see which word-of-mouth is better, so some benefits that can be brought will be more obvious. After all, some values of the model itself are very high, which is indeed necessary Pay more attention to it.

What are the benefits of 3D modeling?

Many things seem to be relatively simple, and it still takes a lot of time to design. I believe that many people want to know the specific benefits when they focus on 3D modeling. This still needs to do some comprehensive analysis. I believe that many people want to know other situations when they choose, according to the situation of the whole model The solution is that we can find that many people are using it now. After all, it will be easier to use the model later.

The first advantage is that when you really pay attention to it, you should realize that the actual value is relatively high, and when you use it, many people can still find that the effect of these modeling is very good. Many people will also find that when they pay attention to the model, the designed products can be operated as a kind of model, and Yee Hing product design is Well done, and many of the models designed are very perfect, different industries, different types are very clear, naturally we can rest assured to choose.

Second, many people think that the effect of 3D modeling is better. When you choose, you still need to see which is better. Only after we have a detailed understanding of these conditions can we know whether it is the best. Many people themselves are considering some comprehensive factors. If the modeling effect is not good, or some other situations, the final result will be The impact is that the whole model is unreasonable and can not be used safely in many occasions. Naturally, we need to pay attention to the good in advance, and we can choose with confidence.

Which industries need 3D modeling?

In fact, modeling is needed in many industries. After all, the common one should be in the construction industry. However, when we really pay attention to 3D modeling, we still need to look at the specific industry used, so that we can make a better choice. Different industries need different modeling methods when they are used, so that we can feel more at ease when we choose, or we can see how to design.

The simplest way is to find a professional design company to draw drawings. With the drawings, the actual modeling will be more relaxed. It is suggested that we can choose Yexing product design. In terms of the overall design concept, it has its own ideas and views, and professional companies will consider many comprehensive factors when designing. Naturally, they will make choices Waiting is also relatively simple.

In addition, only when we have a reasonable understanding of the model of the whole industry can we find out what is the best way for us to choose from the market Only then can know whether can reasonable choice.rapid sheet metal prototyping

To sum up, when many people pay attention to and consider the market situation, they just want to see the advantages of 3D modeling. Only when they understand these, can they feel more at ease when choosing in actual operation, or they can see which is better. After all, according to the existing market situation, it is really necessary to choose products well, so that the whole model can be Better construction.rapid sheet metal prototyping