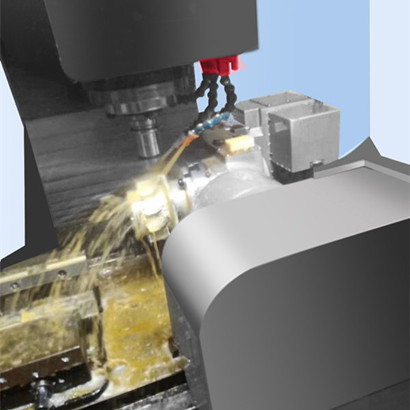

3-5 Axis Machining Services:

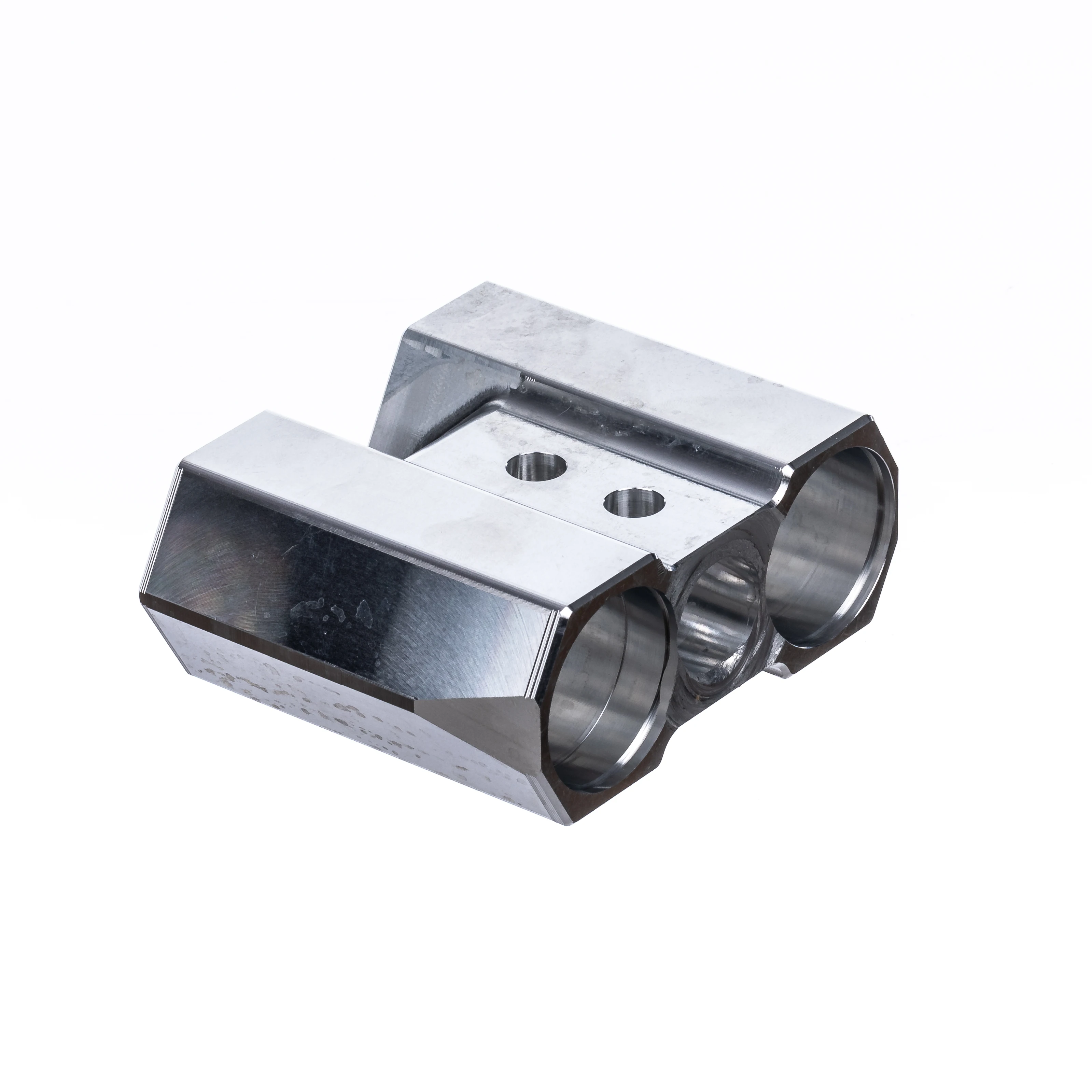

Our team of experienced machinists utilizes cutting-edge technology and state-of-the-art machinery to deliver precise and intricate results. With our 3-5 axis machining services, we can manufacture complex components with multiple dimensions and intricate geometries. This allows us to produce parts with superior accuracy, efficiency, and consistency, meeting the most demanding specifications.

Custom CNC Milling and Turning:

We pride ourselves on our ability to deliver customized solutions that cater to your specific needs. Whether you require prototype machining or the production of custom CNC aluminum parts, our team is equipped to handle projects of any size or complexity. Our CNC milling and turning services offer versatility, allowing us to work with a wide variety of materials, including aluminum, stainless steel, brass, and more.

Prototype CNC Machining:

Innovation and development often require rapid prototyping. Our prototype CNC machining services enable you to transform your ideas into reality quickly and effectively. We work closely with you, ensuring that the prototype accurately represents your vision and meets your design specifications. With our focus on precision and efficiency, we can expedite the prototyping process without compromising quality.

Uncompromising Quality Assurance:

Quality is our top priority. We adhere to stringent quality control measures throughout every step of the machining process. Our team meticulously inspects each component, ensuring it meets or exceeds industry standards. By combining advanced technology and skilled craftsmanship, we deliver products that are durable, reliable, and built to stand the test of time.

Tagline (Tag):

| Name | 6061 7075 cnc milling aluminum parts anodizing aluminum cnc machining fabrication |

| Materials | Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc.Other Special Materials:Lucite/Nylon/wood/titanium/etc |

| Surface Treatment | Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

| Tolerance | +/-0.05mm, 100% QC quality inspection before delivery, can provide quality inspection form |

| Testing equipment | CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement |

| Processing | CNC turning, CNC milling, CNC machining, Laser cutting, Grinding, EDM wire cutting 5 axis cnc milling machining |

| File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| Service Project | To provide production design, production and technical service, mould development and processing, etc |

| Quality Assurance | ISO9001/14000:2015 Certified.SGS |

| Cost Control | 1.The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is lower, at least reducing the trade company's service fee. 2.we consolidate all raw material demand and bought from approved vendor at a mass quantity and right cost with fine quality,Combined with our 15 years of professional CNC machining efficient machining process design experience. Join us to reduce your costs |

| Production Process |

Small details make big difference 1.We promise:All the parts from our company have no sh-arp edge. Holes and screw holes are chamfered for convenient assembly (Under no indication). Every product will be carefully packed to prevent the bump and rust in transit. 2.The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart. 3.Every operator with much experience and they have to double check program,drawing and SOP and tools before action;Operator have to run FA for qualify before mass production;Operator have to check every measure once one setup done to avoid parts scrap in the end. 4.All staff have been training about cost and quality management. Our Professional, Your Satisfaction. |

| production Quality |

1.Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors. 2.Each size of product must be tested one to one after completing production and provide quality report. 3.QC Ensure all parts are 100% inspected before shipment We control it so you don't have to worry |

| Production Progress |

1.We are a combination of production and trade, industry and trade integration business. So far, there are more than 10 cooperative traders in South Korea, Japan and European and American markets; 2.Because we are more close to our factory, we can understand the actual situation of our factory, we are more professional ,more reasonable and more accurate than trade company. So keep you posted on your progress every day. Keep you up to date |

| Production Equipment | We not only have the world of high-end five-axis linkage machining center, the five-axis linkage turning compound double spindle machining center, compound turning machine, but also have more than 20 sets of processing machines from Japanese and Taiwanese brands. Our testing equipment are imported from Japanese brand Mitutoyo, such as high-end automatic three coordinate measuring machine, the two coordinate measuring machine, high-quality height gauge and roughness measurement etc. We stabilize the equipment to ensure your stable product. |

| Custom made | Welcome Customized Make you want to do what you want to be unique,Put Your Good Ideal into Reality. |

| Expedited | According to customer requirements, flexible and rapid temporary deployment to try to meet, Accept Your Special Demands, Let You Save Time and Worries. |

| Material | Aluminum Alloy: 5052 /6061/ 6063 /6082/ 2017 / 7075 / etc. Brass Alloy: 3602 / 2604 / H59 / H62 / etc. Stainless Steel Alloy: 303 / 304 / 316 / 412 / etc. Steel Alloy: Carbon Steel / Die Steel / Spring Steel etc. Other Special Materials: Lucite / Nylon / Bakelite / POM / ABS /PMMA/ PP / PC / PE / PEEK / Titanium etc. We handle many other type of materials. Please contact us if your required material is not listed above. Wide Range for Your Selection. |

| Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting According to customers' specific request. Match Your Products. |

| Usage | Medical equipment, electronic equipment, communication equipment, semiconductor equipment, mechanical equipment, automation equipment, new energy, petroleum, automobile, aviation, motorcycle, bicycle, etc |

| Sample Time and Bulk Time | Sample Time Around 3-7Working Days;Bulk Time Around 8-30Working Days. |

| MOQ | 1pcs, Low MOQ to Avoid Unnecessary Waste of Your Products and Money. |

| Payment Term | T/T,Western Union, Cash, others can be negotiated.Only 30% Deposit, Make YourFloating Capital More Effective. |

| Shipping | By Air or Sea. If Choose by Air, it is Faster Like You Purchase from Local Market. |